How to Make Rubber Hose--2

- Published in Rubber Processing

- Written by Super User

- Be the first to comment!

2.3 Rolling Process

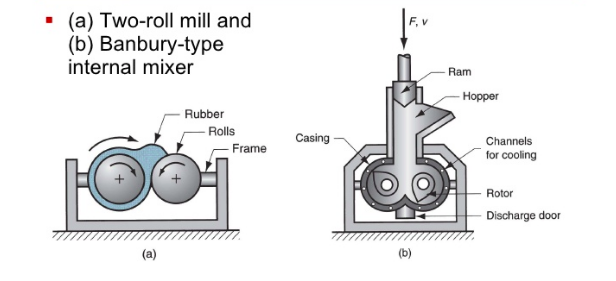

Calendering is the process by which the mixing glue is made into film on the calendering machine or made into a semi-finished cloth with a skeleton material, which includes the operation of laminating, bonding, pressing type and textile hanging glue. The main equipment of the calendering process is calendering machine, calendering machine generally consists of a working roller, a rack, a chassis, a transmission device, a speed regulation and pitch device, a roller heating and cooling device, a lubrication system and an emergency parking device. There are many kinds of calendering machine, the working roller has two, three, four, the arrangement form two rollers have vertical and horizontal; The three rollers have upright, Gamma and triangular; The four rollers have Gamma type, L type, Z type and S type, etc. According to the process use of the main pressure sheet calendering machine (used for calendering film or textile adhesive, most three-roll or four-roller, each roll shape is different), glue calendering machine (used for textile glue, three rollers, each roller has a certain speed ratio, medium roller speed is large.

With the help of speed ratio into the textile), Universal calendering Machine (also known as Universal calendering Machine, both press and glue function, three-roll or four-roll, adjustable speed ratio), pressure type calendering machine, bonding calendering machine and steel wire calendering machine.

The calendering process generally includes the following processes: Preheating and dispensing of the mixing glue; guide and drying of the textile (and sometimes dipping glue)

Adhesive on the four-roll or three-roller calendering machine on the press or on the textile adhesive on the machine calendering semi-finished products cooling, coiling, truncation, placement and so on. Before the calendering, it is necessary to pre-process the rubber and textile, the glue into the calendering machine, it is necessary to first in the heat refinery, this process for heat or preheating, the purpose is to improve the mixing uniformity of the adhesive, further increase plasticity, improve the temperature, increase plasticity.

In order to improve the bonding performance of rubber and textile, to ensure the quality of calendering, it is necessary to dry the fabric, water content control in the 1-2%, low moisture content, fabric hardening, easy to damage in the calendering, high water content, poor adhesion. Several common rubber calendering properties of natural rubber thermoplastic shape, small shrinkage, easy to press, easy to adhere to the hot roller, should control the temperature difference of each roller, so that the film smooth transfer; butyl rubber thermoplastic small, shrinkage, so used for calendering of the adhesive to fully plastic. Because the thermal sensitivity of butadiene rubber to calendering is very significant, the calendering temperature should be lower than the natural rubber, the temperature difference of each roller is high to low; neoprene rubber in 75-95 ℃ easy to stick roller, difficult to delay, should use low temperature method or high temperature method, calendering to quickly cool, mixed with paraffin, hard ester acid can reduce the phenomenon of sticky roller;

Can be operated continuously in a wide temperature range, when the temperature is too low, the glue shrinkage is large, easy to produce bubbles, nitrile rubber thermoplastic small, shrinkage, in the glue type to add filler or softener can reduce shrinkage, when the weight of the filler is more than 50% of the weight of raw rubber, can get smooth surface film, nitrile rubber viscous small sticky cold roller.

2.4 Pressing out process

The pressure-out process is by pressing out the cylinder wall and screw parts of the role, so that the adhesive to achieve the purpose of extrusion and preliminary modeling, the pressure out process has also become extrusion process.

The main equipment for pressing out the process is the pressure out machine. The pressure-out characteristics of several kinds of rubber: natural rubber Press speed is fast, semi-finished product shrinkage is small. Body temperature 50-60 ℃, nose 70-80 ℃, mouth 80-90 ℃; butadiene rubber pressure slow, compression deformation, surface roughness, body temperature 50-70 ℃, head temperature 70-80 ℃, mouth temperature 100-105 ℃; Neoprene press out before the use of full heat, fuselage temperature 50 ℃, nose ℃ , Mouth 70 ℃; ethylene Propylene rubber press speed, shrinkage is small, body temperature 60-70 ℃, nose temperature 80-130 ℃, mouth 90-140 ℃. Nitrile rubber pressure out poor performance, pressure should be fully hot.

The fuselage temperature is 50-60 ℃ and the nose temperature is 70-80 ℃.

2.5 vulcanization Process

Earlier, the main use of natural rubber was simply to do a eraser; it was later used to make small rubber tubes. Until 1823, British chemist Mchintosh invented the dissolution of rubber in coal tar and applied it to a cloth to make tarpaulins that could be used in the manufacture of raincoats and rain boots. However, the raincoat and rain boots melt in the summer and become hard and crisp in the winter. In order to overcome this shortcoming, many people were trying to figure it out at the time. American inventor Charlie Goudeil, who is also experimenting with rubber modification, heats natural rubber and sulfur together in the hope of obtaining a substance that remains dry and elastic at all temperatures throughout the year. He was not successful until February 1839. One day he mixed rubber, sulfur and turpentine into a pot (sulfur was only used for dyeing) and accidentally splashed a mixture of pots onto a scorching stove. To his surprise, the mixture did not melt after falling into the fire, but remained charred as it was, and the remaining incomplete charred mixture in the furnace was elastic. He peeled what had been splashed off the stove, only to find that he had prepared the elastic rubber he wanted.

After continuous improvement, he finally invented the rubber vulcanization technology in 1844. In the production process of rubber products, vulcanization is the last processing process. Vulcanization is the crosslinking process in which rubber macromolecules change from linear structure to mesh structure under certain conditions. The Vulcanization method has three kinds of cold vulcanization, room temperature vulcanization and thermal vulcanization. Most rubber products use thermal vulcanization. Thermal vulcanization equipment has sulfide cans, plate vulcanizer and so on.